Tugger Trains

STILL LiftRunner® Product overview

Patented technology - modern intralogistics

In modern and lean production logistics, it is impossible to imagine an efficient flow of materials without tugger trains. They supply the places of demand, such as assembly stations, with materials in various load carriers and small batch sizes as required. This not only reduces costly logistics space in production, but can also reduce inventories and energy consumption and reduce the risk of accidents by reducing the volume of traffic. With the LiftRunner® tugger trains, STILL offers a complete tugger train system that can be optimally adapted to individual operating conditions.

Our LiftRunner® meet the highest demands for functionality and quality. The patented trolley removal system provides unique ease of use and the lowest rolling resistance in the industry. The different variants of frames and trolleys offer an optimal solution for your individual application - even a demand-specific construction of frames and trolleys is possible. We will be happy to advise you.

LiftRunner® - product overview: The modular components of the tugger trains

The different tugger train components can be combined as desired and are therefore perfectly suitable for any occasion. Tugger trains normally consist of a towing vehicle, up to 4 up to 4 trailers and their assigned trolleys.

Frames

All the different frames act like the wagons of the the tugger train. Beside that, you can use the frames for many different occasions.

LiftRunner® B-Frame

High flexibility with the LiftRunner® B-Frame

- Loading and unloading from both sides for maximum flexibility

- Quiet operation and low wear-and-tear, as trolleys are raised up during the journey

- Excellent driveability and directional stability guarantees a high level of safety

- A straightforward easy-to-use trolley de-coupling system Safe handling with an automatic safety back-up when pushing trolleys

LiftRunner® C-Frame

High load capacity with the LiftRunner® C-Frame

- Flexible indoor and outdoor use

- Excellent driveability and directional stability guarantees a high level of safety

- Quiet operation and low wear-and-tear, as trolleys are raised up during the journey

- Ideal for heavy loads and large containers due to high load capacity

- Safe handling with an automatic safety back-up when sliding trolleys in

E-Frame

- Depending on the orientation, trolleys can be loaded from the right or the left

- Excellent driveability and directional stability guarantees a high level of safety

- Quiet operation and low wear-and-tear, as trolleys are raised up during the journey

- A straightforward easy-to-use trolley de-coupling system

- Safe handling with an automatic safety back-up when sliding trolleys in

Trolleys

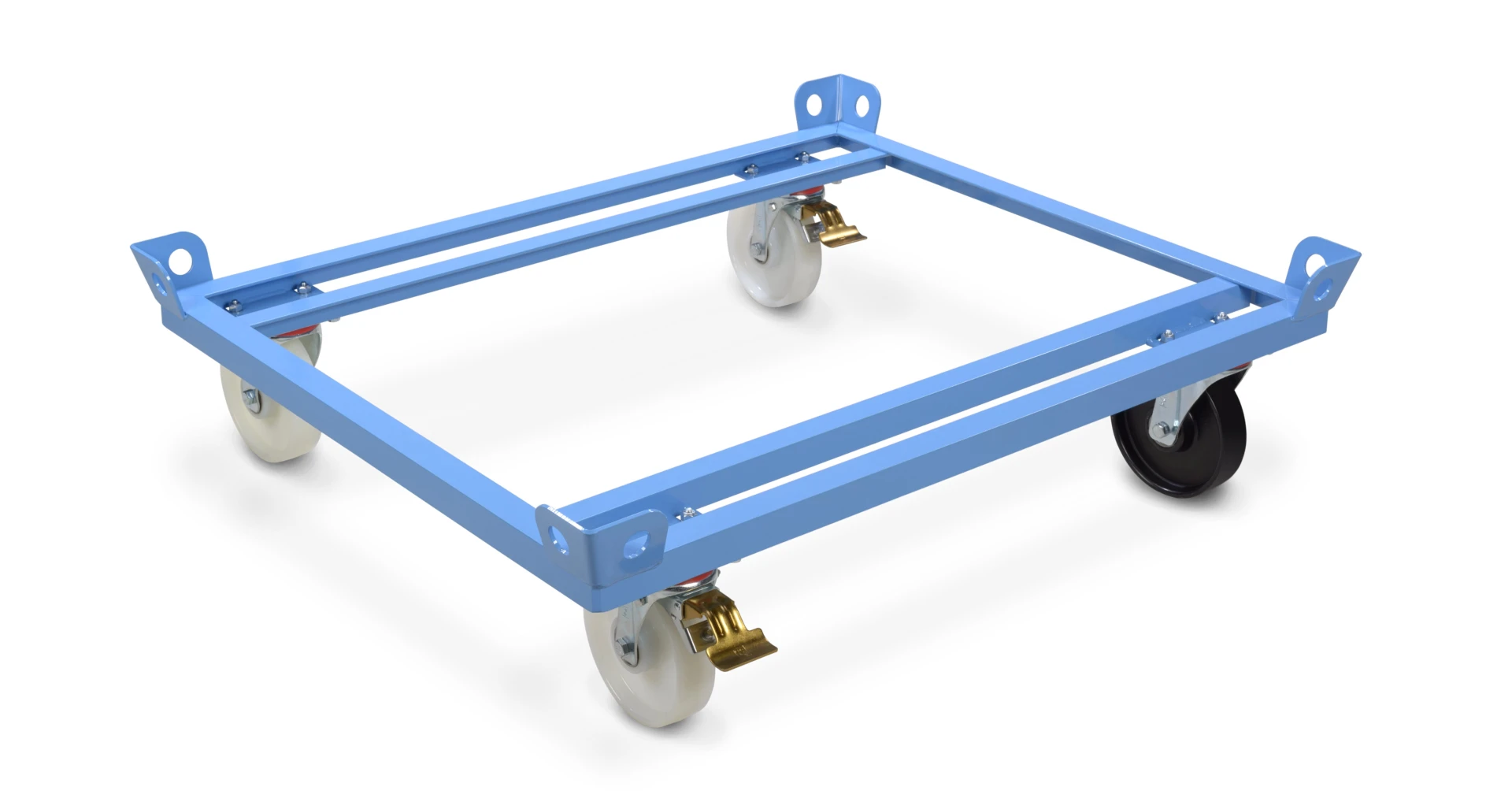

Standard trolley

Foundation of the LiftRunner® System

- Ease of operation, even with high loads, thanks to lower rolling resistance

- The wide range of trolley types for different load-carrying transportation makes it suitable for various applications

- Trolleys are fitted with two brakes as standard for safe operation

- Plastic table trucks with a low deadweight for easier handling come in a variety of different models

Ergonomic tilting function

Ergonomic tilting function and trolleys - a dream team

- suitable for accommodating different material containers

- Compatibility with standard trolleys

- Usability for one person with a load of up to 1000kg

- Ensure ergonomic work by adequate working height and easier handling

- Filling height of 700mm and inclination angle up to 21 °

Towing vehicles - STILL's electric tractors

The STILL LTX electric tractor tows the LiftRunner® B- C-, and E-frames which carry the rolling load carriers (trolleys) easily and safely.